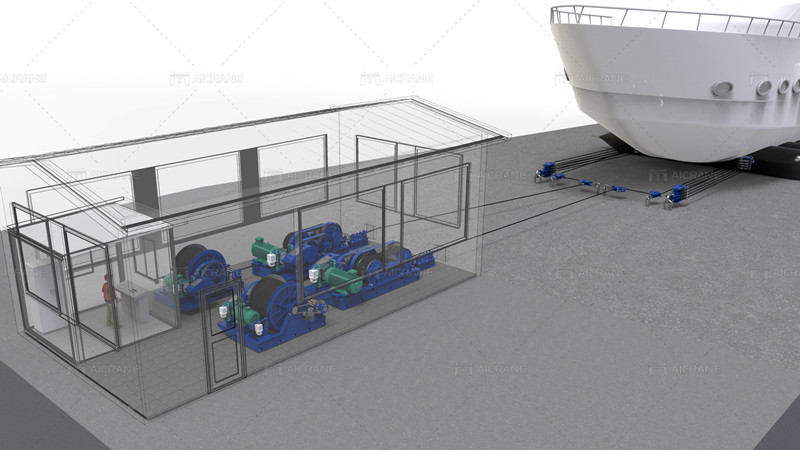

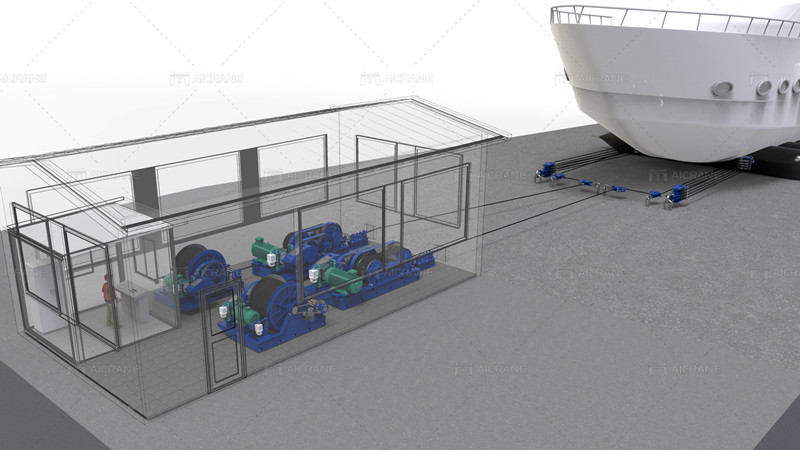

Slipway winches play a crucial role in the maritime industry, facilitating the launching and hauling of vessels in and out of slipways. These winches are integral to shipyard operations, providing the necessary pulling power and control for a smooth and controlled movement of boats and ships. Various types of slipway winches exist, each designed to meet specific requirements and operational scenarios within shipyards. Let’s explore the different types of slipway winches and their applications in marine industries.

Electric Slipway Winch

Electric slipway winches are powered by electric motors, offering a clean and efficient source of energy. These winches are known for their precise control and ease of operation. Electric slipway winches find applications in shipyards and marinas where a reliable and controllable pulling force is essential for the launching and recovery of boats. The electric power source allows for variable speed control, making them suitable for various vessel sizes and weights. Contact the manufacturer to get customized solutions.

Hydraulic Slipway Winch

Hydraulic slipway winches utilize hydraulic power to generate the pulling force needed for vessel movement. These winches are characterized by their high power density and ability to generate substantial force, making them suitable for handling larger vessels. The hydraulic system provides smooth and consistent operation, and the winch can be easily controlled for precise maneuvers. Hydraulic slipway winches are often preferred for heavy-duty applications in larger shipyards and facilities.

Manual Slipway Winch

Manual slipway winches are operated by hand, requiring physical effort from the operator to turn the winch drum and generate pulling force. While not as commonly used in large shipyards, manual slipway winches find applications in smaller boatyards and marinas where the workload may be lighter, and the simplicity of operation is preferred. These winches are cost-effective and can be suitable for smaller vessels or as auxiliary winches in specific scenarios.

Pneumatic Slipway Winch

Pneumatic slipway winches operate using compressed air as their power source. These winches are valued for their versatility, especially in environments where electricity or hydraulics may pose challenges. Pneumatic slipway winches are known for their safety and reliability, particularly in situations where there is a risk of electric sparks. They find applications in shipyards and maintenance facilities where compressed air systems are readily available.

Anchor Handling Slipway Winch

Anchor handling slipway winches are specialized winches designed for the handling of anchors on vessels. These winches provide the necessary power and control to deploy, retrieve, and secure anchors during maritime operations. Anchor handling is a critical aspect of vessel movement, and these winches are equipped with features such as anchor brakes and tension monitoring to ensure safe and efficient handling.

Tugger Slipway Winch

Tugger slipway winches are designed for use in conjunction with tugboats or other assisting vessels during the launching or hauling of ships. These winches provide additional pulling force to assist in the controlled movement of vessels within the slipway. Tugger winches play a vital role in ensuring precise positioning and alignment of vessels during the launch or recovery process, contributing to overall safety and efficiency.

Rope Winch

Rope winches are a common type of slipway winch that uses a robust rope or cable to generate pulling force. These winches are versatile and suitable for various applications, including the launching and hauling of vessels. The choice of rope material and construction depends on factors such as the weight of the vessels, environmental conditions, and the specific requirements of the shipyard.

Wire Winch

Wire winches utilize steel wire ropes as the primary means of generating pulling force. The strength and durability of steel wire make these winches suitable for handling heavy loads and large vessels. Wire winches are known for their reliability and are commonly used in shipyards with a focus on heavy-duty shipbuilding and maintenance operations.

Synthetic Rope Winch

Synthetic rope winches, often made from materials like high-strength polymers, provide a lightweight yet robust alternative to traditional steel wire ropes. These winches offer advantages such as reduced weight, increased flexibility, and corrosion resistance. Synthetic rope winches are suitable for specific marine winch applications where these characteristics are beneficial.

Clutched Slipway Winch

Clutched slipway winches feature a clutch mechanism that allows for disengagement and engagement of the drum, providing greater control over the pulling process. This type of winch is advantageous when precise and intermittent pulling is required, allowing the operator to engage and disengage the winch quickly.

Brake Slipway Winch

Brake slipway winches are equipped with specialized braking systems to ensure controlled and safe stopping of the pulling operation. These winches are essential for scenarios where the vessel’s movement needs to be halted promptly and securely.

Automatic Slipway Winch

Automatic slipway winches are designed with automated features, allowing for programmable and hands-free operation. These winches may include sensors, control systems, and monitoring devices that enable the automation of certain functions, contributing to increased efficiency and reduced manual intervention.

Remote-Controlled Slipway Winch

Remote-controlled slipway winches provide operators with the flexibility to control the winch from a distance. This feature is particularly valuable in situations where the operator’s direct proximity to the winch may pose safety risks. Remote control enhances visibility and allows for precise control of the winching operation.

Heavy-Duty Slipway Winch

Heavy-duty slipway winches are specifically designed for handling the substantial weight and size of large vessels. These winches are equipped with reinforced components, powerful motors, and advanced control systems to meet the demands of heavy-duty shipbuilding and maintenance operations.

Compact Slipway Winch

Compact slipway winches are designed for use in limited spaces or on smaller slipways. These winches retain the essential features of larger counterparts but are engineered for a more compact footprint, making them suitable for facilities with space constraints.

In conclusion, the diverse types of slipway winches cater to the varying needs and conditions of shipyards and marine facilities. The choice of a particular type of winch depends on factors such as the size of vessels, the frequency of operations, available power sources, and specific operational requirements. The continuous advancements in winch technology continue to contribute to the efficiency, safety, and versatility of slipway operations in the maritime industry.