Maintenance is a crucial aspect of ensuring the optimal performance, longevity, and safety of any industrial equipment, and a 50 ton winch is no exception. Regular and proactive maintenance practices can prevent breakdowns, reduce downtime, and extend the lifespan of the winch. Below is a comprehensive guide on the maintenance of a 50 ton winch, covering various aspects such as lubrication, inspection, and troubleshooting.

Lubrication

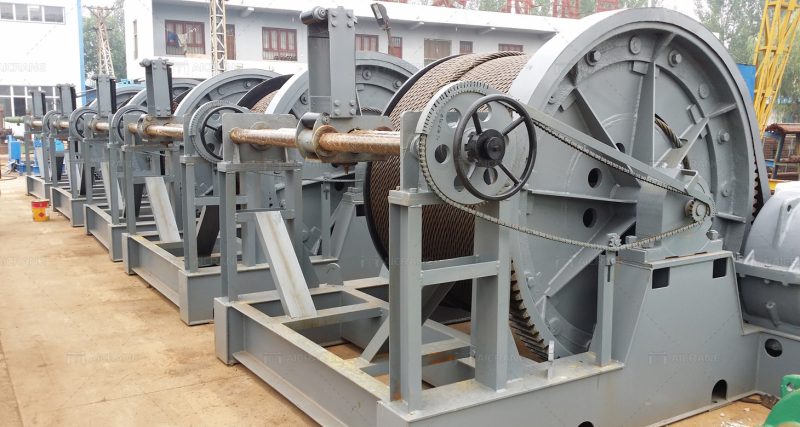

Proper lubrication is fundamental to the smooth operation of a 50 ton winch. The moving parts, such as bearings, gears, and chains, should be adequately lubricated to reduce friction, prevent wear, and minimize heat generation. Here are key points to consider:

Use high-quality lubricants suitable for the winch’s operating conditions.

Establish a regular lubrication schedule based on the manufacturer’s recommendations.

Pay special attention to load-bearing components, ensuring they receive sufficient lubrication.

Monitor lubricant levels and replenish them as needed.

Inspection and Cleaning

Regular inspections and cleaning are essential for identifying potential issues before they escalate. A systematic approach to inspection can help maintain the winch in optimal condition. Consider the following:

Inspect the winch structure for signs of wear, corrosion, or damage.

Examine wire ropes or cables for fraying, kinks, or other abnormalities.

Check for loose or damaged fasteners and connections.

Clean dirt, debris, and contaminants from the 50 ton winch components.

Ensure that the electrical components are free from dust and moisture.

Wire Rope Inspection

The wire rope is a critical component of the winch, and its condition directly impacts safety and performance. Implement the following practices for wire rope maintenance:

Regularly inspect the entire length of the wire rope for visible damage.

Conduct non-destructive testing (NDT) methods, such as magnetic particle inspection or ultrasonic testing, to detect internal flaws.

Remove and replace any wire rope showing signs of wear, corrosion, or fatigue.

Lubricate the wire rope to minimize friction during operation.

Electrical System Checks

The electrical system of the winch plays a pivotal role in its overall functionality. To ensure a reliable and safe electrical system of the electric winch, adhere to the following maintenance tasks:

Inspect the condition of electrical cables for wear, damage, or exposed wiring.

Check the connections, terminals, and electrical components for signs of overheating.

Test the functionality of controls, limit switches, and emergency stop mechanisms.

Perform routine calibration checks on load indicators and other monitoring systems.

Brake System Inspection

The brake system is critical for the safety of winch operations. Regular inspections and testing of the brake system are essential:

Inspect brake pads or linings for wear and replace them as necessary.

Check the brake system for proper adjustment and alignment.

Test the emergency brake function to ensure it activates promptly.

Monitor brake fluid levels in hydraulic brake systems and replenish as needed.

Structural Integrity

The structural integrity of the winch must be maintained to ensure safe and reliable operation. Consider the following measures:

Inspect welds and structural components for cracks, deformities, or signs of stress.

Verify that the winch frame, drum, and other structural elements are securely mounted.

Address any issues related to misalignment or excessive vibrations during operation.

Troubleshooting and Repairs

In addition to routine maintenance, prompt troubleshooting and repairs are essential when issues arise. Maintain a log of reported problems, conduct root cause analysis, and implement corrective actions. Addressing problems early can prevent extensive damage and costly repairs.

Operator Training

Invest in comprehensive training programs for winch operators. Well-trained operators are more likely to identify potential issues during routine operation and can contribute to a proactive maintenance culture.

A well-maintained 50 ton winch is a reliable asset that contributes to operational efficiency and safety. By implementing a comprehensive maintenance program that includes lubrication, inspections, wire rope care, electrical system checks, brake system inspections, structural integrity assessments, troubleshooting, and operator training, businesses can maximize the lifespan and performance of their winches. Regular maintenance not only reduces the risk of unexpected breakdowns but also ensures that the winch operates at its full capacity, meeting the demands of heavy-duty lifting applications. Contact your winch manufacturer to get more information of maintenance.