Rail Mounted Gantry (RMG) cranes are essential pieces of equipment in container handling operations at ports and container terminals. These massive gantry cranes play a vital role in efficiently moving containers from ships to storage yards and vice versa. Understanding the operation of RMG container gantry cranes is crucial for those involved in the shipping and logistics industry. In this comprehensive guide, we will explore the various aspects of RMG crane operation, from their components and functions to the safety protocols that ensure smooth and secure container handling.

I. What is an RMG Container Gantry Crane?

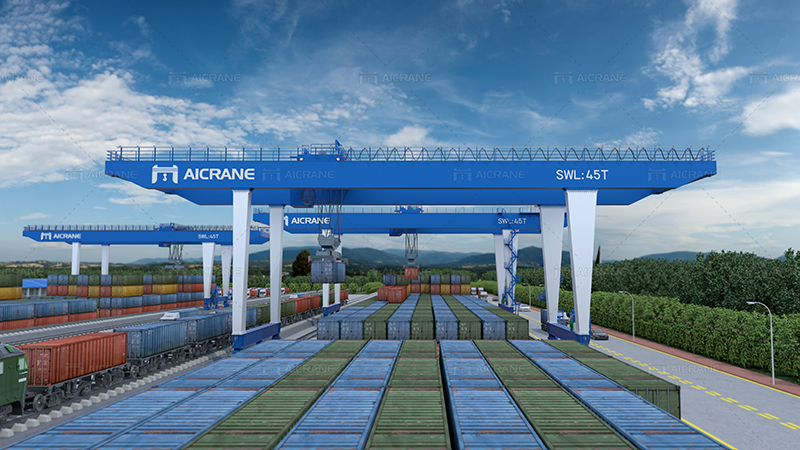

A Rail Mounted Gantry (RMG) crane, also known as a Container Gantry Crane, is a specialized handling machine used primarily in container terminals. Unlike mobile harbor cranes, RMG cranes are designed for fixed operations, typically within the container yard of a port or intermodal terminal. They are called “rail mounted” because they are mounted on rails, allowing them to move quickly and efficiently along rail tracks laid on the terminal’s pavement.

RMG cranes are renowned for their high efficiency, accuracy, and ability to stack containers in a precise and organized manner. They are electrically powered, contributing to reduced emissions and lower operating costs compared to diesel-powered alternatives.

II. Components of an RMG Container Gantry Crane

To understand the operation of an RMG crane, it’s essential to know its major components and their functions:

- Gantry Structure: The gantry structure is the main frame of the crane, consisting of vertical legs connected by horizontal beams. This structure houses the crane’s machinery, including the trolley, spreader, and drive systems.

- Trolley: The trolley is a movable platform that runs along the gantry structure’s horizontal beams. It carries the spreader, which is responsible for lifting and lowering containers. The trolley’s movement allows precise positioning of containers during loading and unloading operations.

- Spreader: The spreader is the component that attaches to the trolley and interfaces with the containers. It can be adjusted to accommodate various container sizes and types, such as standard ISO containers or specialized containers.

- Wheels and Axles: RMG cranes are mounted on rails with individual wheels and axles. These tires allow the crane to move along the rail tracks in the container yard, providing mobility and access to different stacks of containers.

- Drive Systems: RMG cranes are equipped with electric drive systems, including motors, gears, and controls, to facilitate precise and smooth movement. These systems ensure that the crane can be positioned with accuracy.

- Electrical and Control Systems: Modern RMG cranes rely on advanced electrical and control systems to manage crane operations, including load handling, trolley movement, and safety features. These systems are crucial for the crane’s overall performance and safety.

III. RMG Container Gantry Crane Operation

The operation of an RMG crane involves several steps and requires a skilled crane operator. Here’s a general overview of how RMG container gantry cranes work:

- Start-Up Procedures: Before operation, the crane operator conducts a series of start-up procedures. This includes checking the crane’s systems, ensuring all safety mechanisms are functioning correctly, and inspecting the spreader for any visible issues.

- Container Retrieval: To unload containers from a ship, the RMG crane is positioned near the ship’s side. The spreader is lowered and attached to the container to be unloaded. The crane operator carefully raises the container and moves it to the designated storage area.

- Stacking Containers: When stacking containers in the storage yard, the RMG crane moves containers from the trolley to their designated positions within the container stack. The crane operator uses precision controls to ensure the containers are stacked safely and securely.

- Container Delivery: When loading containers onto a ship or another mode of transport, the RMG crane retrieves containers from the storage yard, hoists them, and moves them to the ship’s deck or other designated location.

- Safety Precautions: Safety is paramount in RMG crane operations. The operator must follow strict safety protocols, including ensuring that the area around the crane is clear of personnel and vehicles and that containers are securely attached to the spreader to prevent accidents.

- Remote Operation: Many modern RMG cranes can be operated remotely from a control room, allowing for greater precision and safety. Operators use advanced technology and camera systems to monitor and control the crane’s movements.

IV. Safety Protocols and Training

Safety is a top priority in RMG container gantry crane operations. Strict safety protocols and ongoing training for crane operators are crucial to prevent accidents and ensure smooth operations. Here are some essential safety measures:

- Personnel Exclusion Zones: Clear exclusion zones are established around the crane during operation to prevent accidents. No personnel or vehicles should be in these areas while the crane is operating.

- Regular Maintenance: Routine maintenance and inspections are essential to keep the crane in optimal condition. This includes checking electrical systems, gears, and safety mechanisms.

- Emergency Stop Procedures: Crane operators are trained to execute emergency stop procedures in case of any unforeseen issues or malfunctions.

- Weather Considerations: Adverse weather conditions, such as strong winds, can affect crane operations. Operators must be aware of weather conditions and take necessary precautions.

- Operator Training: Crane operators undergo extensive training to understand the crane’s controls, safety protocols, and the intricacies of container handling.

- Use of Safety Equipment: Operators must use appropriate safety equipment, such as helmets, safety harnesses, and communication devices, to ensure a secure working environment.

Conclusion

RMG container gantry cranes are the workhorses of container handling operations in ports and intermodal terminals. Understanding their components, operation, and safety protocols is essential for those involved in the shipping and logistics industry. These gantry cranes offer remarkable efficiency and precision in container handling, but this comes with the responsibility of adhering to strict safety measures and ensuring proper maintenance to prevent accidents and maintain reliable performance. With the continued growth of global trade and the demand for container handling, RMG cranes remain a crucial part of the supply chain, making the knowledge of their operation invaluable.