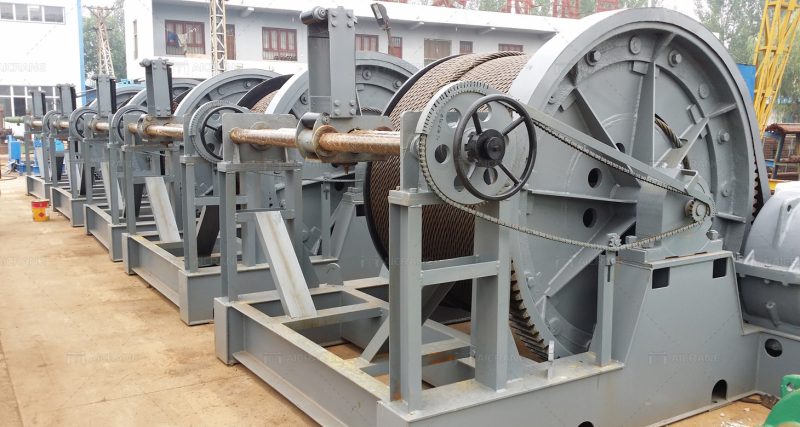

Repairing a 100 ton winch requires a systematic and thorough approach to address any issues affecting its performance. These powerful machines are essential for heavy-duty lifting and pulling operations, and proper maintenance is crucial for their longevity and reliability. In this comprehensive guide, we will explore the step-by-step process of fixing a 100 ton winch, covering common issues, troubleshooting techniques, and safety considerations.

Diagnostic Inspection

The first step in fixing a 100 ton winch is to conduct a comprehensive diagnostic inspection. This involves a detailed examination of the entire winch system to identify the root cause of the problem. Key areas to focus on during the inspection include:

Visual Inspection: Examine the winch for any visible signs of damage, wear, or misalignment. Inspect wire ropes, cables, drum, and other components for abnormalities.

Electrical Components: Check the electrical system, including wiring, connections, control panels, and motors. Look for loose connections, damaged wires, or signs of electrical malfunctions.

Mechanical Components: Inspect mechanical components such as gears, bearings, and the drum for wear, damage, or misalignment. Check for leaks in the gearbox and ensure that all moving parts operate smoothly.

Safety Features: Verify the functionality of safety features, including limit switches, emergency stop systems, and overload protection mechanisms.

Load Testing: If the winch has been experiencing capacity-related issues, perform load testing to assess its lifting capabilities and identify any weaknesses.

Identify Specific Issues

Based on the diagnostic inspection, identify specific issues affecting the winch’s performance. Common problems may include:

Wire Rope Issues: Fraying, kinks, or broken strands in the wire ropes can compromise lifting capacity and safety.

Electrical Malfunctions: Problems with the control panel, wiring, or electrical components can result in operational failures.

Mechanical Wear: Gears, bearings, and other mechanical parts may experience wear and tear, affecting the winch’s efficiency.

Safety Feature Failures: Malfunctions in limit switches, emergency stop systems, or overload protection mechanisms can pose serious safety risks.

Safety Precautions

Before attempting any repairs, ensure that proper safety precautions are in place. This includes:

Lockout/Tagout Procedures: Implement lockout/tagout procedures to isolate the winch from its power source and prevent accidental start-ups.

Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves, eye protection, and any other necessary safety gear.

Secure the Work Area: Ensure that the work area is clear of obstacles, and use barricades or warning signs to prevent unauthorized access.

Follow Manufacturer Guidelines: Refer to the guidelines of winch manufacturer and safety instructions for specific precautions and recommendations.

Wire Rope Replacement

If the issue involves wire rope damage, replacement may be necessary. Follow these steps for wire rope replacement:

Secure the Winch: Lock the winch in a stationary position and ensure it is safely secured.

Remove the Damaged Rope: Unwind and remove the damaged wire rope carefully, avoiding kinks or snags.

Install the New Wire Rope: Thread the new wire rope through the winch drum and secure it according to the manufacturer’s guidelines.

Proper Tensioning: Ensure the wire rope is properly tensioned to prevent slack and maintain lifting capacity.

Electrical System Repairs

For electrical issues, follow these general steps:

Isolate Power Source: Ensure the winch is disconnected from the power source to prevent electrical hazards.

Inspect Wiring: Examine the wiring for any visible damage, wear, or loose connections. Repair or replace damaged wiring as needed.

Check Control Panels: Verify the functionality of control panels, switches, and indicators. Repair or replace any malfunctioning components.

Motor Inspection: Inspect electrical motors for signs of overheating, unusual noise, or vibration. Address any motor issues promptly.

Mechanical Component Repairs

When dealing with mechanical issues, follow these steps:

Gear and Bearing Inspection: Inspect gears and bearings for wear, damage, or misalignment. Replace any components that show signs of deterioration.

Drum Surface: If the drum surface is uneven or shows signs of excessive wear, consider resurfacing or replacing it.

Gearbox Inspection: Check the gearbox for leaks and proper lubrication. Address any leaks and replace lubricants as needed.

Alignment Checks: Ensure that all mechanical components are properly aligned to prevent unnecessary stress and wear.

Safety Feature Restoration

Repair or replace any malfunctioning safety features:

Limit Switches: Adjust or replace limit switches that may be preventing the winch from reaching its specified travel limits.

Emergency Stop System: Test and repair the emergency stop system to ensure its immediate response in case of an emergency.

Overload Protection: Calibrate and test the overload protection system to prevent the heavy duty winch from exceeding its rated capacity.

8Load Testing and Calibration:

After completing the necessary repairs, perform load testing and calibration to validate the winch’s performance:

Load Testing: Gradually apply loads to the winch, monitoring its response and ensuring it can handle the specified weights without issues.

Calibration of Instruments: Calibrate load indicators, limit switches, and other monitoring instruments to ensure accurate readings and adherence to safety standards.

Documentation

Keep detailed records of all repairs and maintenance activities:

Maintenance Log: Document the specifics of each repair, including parts replaced, adjustments made, and testing results.

Manufacturer Guidelines: Refer to the winch’s manufacturer guidelines for recommended maintenance schedules and procedures.

Post-Repair Inspection

Conduct a final inspection to ensure all repairs were successful:

Operational Tests: Test the winch under various conditions to verify that all issues have been addressed.

Visual Inspection: Perform a final visual inspection to ensure that all components are in good condition.

Fixing a 100 ton winch requires a methodical and safety-conscious approach. Whether addressing issues with wire ropes, electrical systems, mechanical components, or safety features, following a systematic process is essential. Regular maintenance and prompt repairs contribute to the reliability and longevity of the winch, ensuring its continued safe and efficient operation in heavy-duty lifting and pulling applications. Always prioritize safety, adhere to manufacturer guidelines, and document all maintenance and repair activities for future reference.