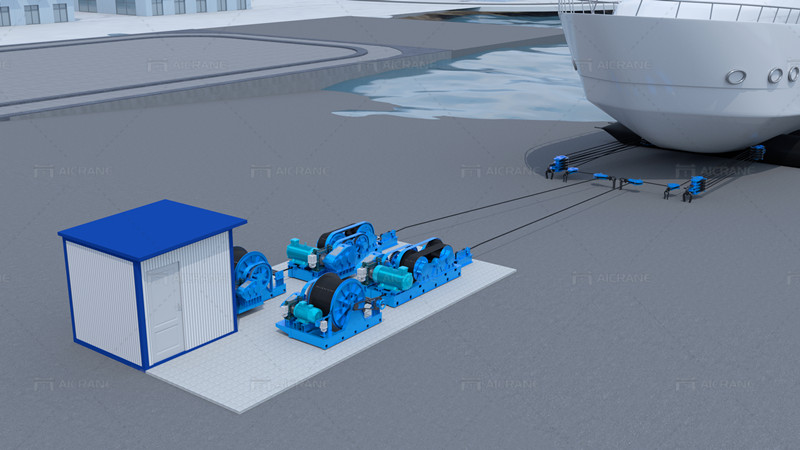

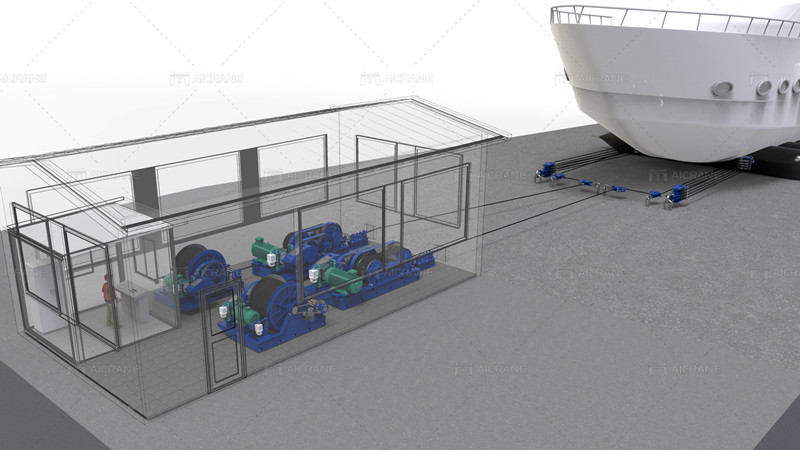

Fixing a slipway winch with a rail trolley requires careful planning, technical expertise, and adherence to safety protocols. Slipway winches are essential equipment used in marine environments for launching and retrieving vessels, while rail trolleys provide the necessary mobility and stability for the winch system. Here are the steps involved in fixing a slipway winch with a rail trolley:

Assessment and Planning

Before beginning any repair or fixing work, conduct a thorough assessment of the slipway winch and rail trolley system. Identify any damaged or malfunctioning components, such as motors, gears, cables, or structural elements. Plan the repair process, including the tools, equipment, and materials needed.

Safety Precautions

Ensure that proper safety precautions are in place before starting the fixing process. This includes wearing personal protective equipment (PPE) such as gloves, eye protection, and hard hats. Additionally, secure the work area to prevent unauthorized access and potential hazards.

Disconnect Power Supply

Before working on the winch or rail trolley, disconnect the power supply to avoid electrical accidents. Follow proper lockout/tagout procedures to isolate the electrical circuits and ensure that the equipment cannot be energized accidentally.

Inspect and Repair Components

Begin by inspecting the various components of the slipway winch and rail trolley. Check for signs of wear, corrosion, loose connections, or damaged parts. Replace any worn-out or damaged components, such as cables, pulleys, bearings, or brake systems.

Lubrication and Maintenance

Apply lubricants to moving parts and mechanisms, such as gears, bearings, and cables, to ensure smooth operation and prevent friction-related issues. Perform routine maintenance tasks, such as cleaning, greasing, and adjusting, to keep the marine winch and rail trolley in optimal condition.

Alignment and Calibration

Check the alignment of the rail trolley tracks and ensure that they are straight, level, and securely fastened to the ground or support structure. Use alignment tools and measurements to verify proper alignment. Calibrate the winch system to ensure accurate operation and load capacity.

Testing and Commissioning

After completing the fixing process, conduct thorough testing and commissioning of the slipway winch with the rail trolley. Test the winch’s lifting and lowering functions, as well as the rail trolley’s movement along the tracks. Verify that all safety features, such as limit switches, emergency stop buttons, and overload protection, are functioning correctly.

Training and Documentation

Provide training to operators and maintenance personnel on the proper use, operation, and maintenance of the slipway winch and rail trolley system. Create documentation, including maintenance schedules, repair records, and safety procedures, to ensure ongoing compliance and safety.

Regular Inspections and Maintenance

Implement a regular inspection and maintenance program for the slipway winch and rail trolley system. Schedule periodic inspections, lubrication, and testing to identify and address any potential issues before they escalate.

Emergency Response Plan

Develop an emergency response plan that includes procedures for addressing equipment failures, accidents, and evacuation protocols. Ensure that personnel are trained in emergency response procedures and have access to emergency contact information.

In conclusion, fixing a slipway winch with a rail trolley requires meticulous planning, safety precautions, thorough inspection, repairs, testing, and ongoing maintenance. By following these steps and prioritizing safety and reliability, you can ensure the efficient and safe operation of the slipway winch and rail trolley system in marine environments. Get more information about how to fix slipway winch from a reliable winch manufacturer.